Research - Journal of Environmental and Occupational Health (2022)

Impact of Environmental Pollution on the Residents of Sharada from Tannery Industries, Kano, Northwestern Nigeria

Dave Eleojo Ekpa*Dave Eleojo Ekpa, Institute of Ecology and Environmental Studies, Obafemi Awolowo University, Ile-Ife, Nigeria, Email: daveekpa@gmail.com

Received: 22-Nov-2022, Manuscript No. JENVOH-22-80701; Editor assigned: 25-Nov-2022, Pre QC No. JENVOH-22-80701(PQ); Reviewed: 12-Dec-2022, QC No. JENVOH-22-80701; Revised: 19-Dec-2022, Manuscript No. JENVOH-22-80701(R); Published: 26-Dec-2022

Abstract

Environmental pollution has become a worldwide challenge due to industrialisation and anthropogenic activities. Industrial effluents cause a wide scope of environmental problems with health hazards and these challenges are more complex and critical now than before, in developing countries like Nigeria. This study assessed the impact of environmental pollution and determined levels of heavy metals (HMs) in the effluents from tannery industries in Sharada phase I and II. The data used include laboratory test’s results to determine heavy metals (Cd, Cr, Cu, Pb, Zn, Ni, Mn, Fe), Electrical Conductivity (EC) and Total Dissolved Solid (TDS) from industrial effluents. Interview was conducted and systematic field observation was employed to ascertain the perceptible impacts of the pollution on the environment. The finding reveals that concentrations of the physicochemical parameters are within the Federal Environmental Protection Agency (FEPA) acceptable limits but the EC and TDS are above the limit. The pH value of the effluents is neutral. The major conspicuous and dangerous environmental challenges in the study area include air pollution and open drainages. The economic activities of the residents are negatively affected due to stink from the effluents and untidy environment. The environment has become detrimental to people’s health and the passerby. Thus, FEPA laws should be enforced, the industries should construct closed drainage, and study on Environmental Impact Assessment (EIA) should be conducted often to curtail the environmental challenges in the area in order to make the environment conducive for living, avoid further deterioration and ensure a sustainable hygienic environment.

Keywords

Impact; Injury; Environmental Pollution; Residents; Industries

Introduction

A physical Pollution is one of the major environmental challenges that are threatening many lives globally. Environmental pollution is the negative alteration of the state or quality of an environment resulting in negative impacts on human health, animals, plants and soil. In Nigeria, industrial pollution is still a serious problem in spite of the efforts by the government to control the menace to ensure that Nigerians live in a sanitized and disease free environment. Fereidoun et al. ( 2007) asserted that there are numerous industries established in Nigeria that cause pollution, among which are tanneries, textiles, petroleum refinery, chemicals and plastics, food and beverages, breweries, soaps and detergents [1]. Pollution is caused by anthropogenic activities and natural forces. Over time industries have become the major contributors of environmental pollution. Gana and Toba et al. (2015). Opined that the extent of industrial pollutants damage to health and the environment is directly proportional to the increase in industries and the rate of production as well as consumption of products [2]. Textile, cellulose and various chemicals productions are usually associated with synthetic dyes usage with other toxic metals and the discharge of their effluents could have a serious hazardous influence on the environment [3]. It is high time to take proactive actions by the government and other responsible agencies to curb the issue of environmental pollution and degradation in every nook and cranny in Nigeria so as to protect the natural environment and lives. To ensure a conducive and sustainable productive environment man must avoid environmental pollution. For decades Nigerian cities have been confronted with high level of pollution of which is responsible for several challenges to human health. In Kano state environmental pollution has been one of the prevailing challenges in many locations particularly industrial areas and the tannery industries located in Sharada area of Kano are among the major sources of environmental pollution. This calls for adequate assessment of water pollution and determination of heavy metals concentration in the effluents that are discharged to the environment. This has become a great concern for the responsible institutions and environmental agencies as this menace has currently reached an alarming rate that needs urgent attention. Therefore, this study focused on ascertaining the levels of heavy metals present in the effluents discharged to the environment from tannery industries in Sharada phase I and II.

Materials and Methods

Study area

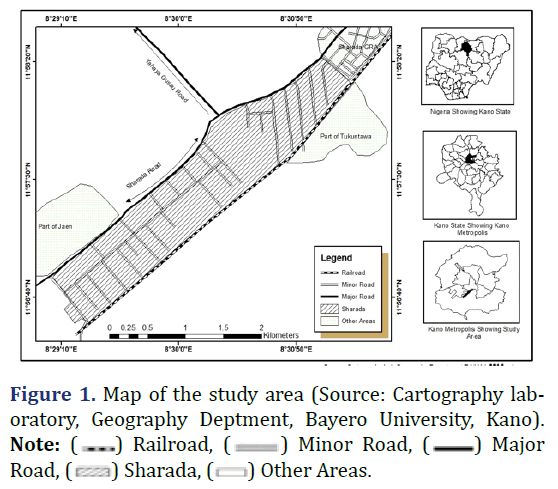

Sharada the study area is located in Kano Municipal Local Government Area (LGA) and it is one of the renowned industrial estates in Kano State. It is located at the southern part of the ancient Kano city and it is situated between latitude 110 57’30” N, and longitude 8030’50’’E (Figure 1). Sharada LGA, boarded with Bayero University, Kano road to the North, Gidan Maza to the South, Gandu to the East and Dorayi Karama to the West. Sharada area is a mixture of many types of industries including heavy, light, wet, dry, food, household, and plastic, among others. The climate of Sharada is the same as Kano metropolis’ which is tropical dry and wet climate classified as AW by Koppen. The climate of the study area is the tropical dry-and-wet type, classified by Koppen’s as Aw. The movement of the Inter- Tropical Discontinuity (ITD) gives rise to two seasons (wet and dry seasons). The wet season lasts from May to mid-October with a peak in August while the dry season extends from mid-October of one calendar-year to mid- May of the next. The annual mean rainfall is between 800 mm to 900 mm; and variations about the annual mean values are up to ± 30%. The mean annual temperature is about 260˚C [4].

Data source

This study used primary and secondary data which include a laboratory test’s results of the heavy metals, interview, observation and relevant information from previous works. The laboratory test was carried out on all the industrial effluents samples that were collected from the study area and heavy metals such as Cd, Cr, Cu, Pb, Zn, Ni, Mn, Fe and physical parameters like Electrical Conductivity (EC) and Total Dissolved Solid (TDS) were analysed in the laboratory. Interview was conducted for some industrial personnel and residents of the study area. Furthermore, a systematic observation was employed to see the visible impacts of the pollution on the environment.

The study was undertaken within Sharada phase I and II industrial areas where two tannery industries are located. The effluents samples were collected from Sharada Phase I and II through the major parts where the industrial effluents flow in the study area. In 2016, industrial effluents were collected from the tannery A and B in the study area. The first two effluents samples were collected separately from the tannery A and B discharge channels while the other samples were collected as mixture of effluents from both tanneries. The effluents samples were properly labeled before taking them to the laboratory for test. Table 1 shows the 2016, industrial effluents samples from two tannery industries in Sharada Phase I and II. Descriptive statistic was used in analyzing the data collected from the field and laboratory test. The average concentration of each parameter in the industrial effluents were determined and compared with the Federal Environmental Protection Agency (FEPA) permissible limits.

Results and Discussion

Laboratory analysis of parameters and their characteristics

Industrial effluents cause a wide scope of environmental problems and health hazards. These challenges are becoming more complex and critical not only in developing countries like Nigeria but also in developed countries. Table 1 shows the average concentration of physiochemical properties of the industrial effluents from Tannery A and B.

| Parameters | Average Value | Fepa Tolerance Limit |

|---|---|---|

| Electrical Conductivity (μS/cm) | 14442 | 1200 μS/cm |

| Total Dissolved Solid (mg/l) | 8660 | 2000 (mg/l) |

| pH (mg/l) | 7 | 6-9 (mg/l) |

| Copper (mg/l) | 0.004 | Less than human 1 (mg/l) |

| Lead (mg/l) | 0.0055 | Less than 1 (mg/l) |

| Cadmium (mg/l) | 0.0054 | Less than 1 (mg/l) |

| Zinc (mg/l) | 0.0026 | Less than 1 (mg/l) |

| Nickel (mg/l) | 0.0012 | Less than 1 (mg/l) |

| Iron (mg/l) | 0.0028 | 20 (mg/l) |

| Calcium (mg/l) | 0.0178 | 200 (mg/l) |

| Manganese (mg/l) | 0.0035 | 5 (mg/l) |

| Chromium (Trivalent and Hexavalent) (mg/l) | 0.0024 | Less than (mg/l) an 1 |

Analysis of concentration of electrical conductivity, total dissolved solid and pH value

The findings in Table 1 reveals that the average concentration of all the physicochemical parameters of the industrial effluents are within the acceptable limits except for the Electrical Conductivity and Total Dissolved Solid which have large disparity between the FEPA tolerant value. The average concentration of the Electrical Conductivity is 14442 μS/cm while the FEPA standard limit is 1200 μS/cm and on the other side the average concentration of the Total Dissolved Solid in the effluents is 8660 mg/l which exceeded the acceptable limit of FEPA (2000 mg/l). This implies that there is a significant difference between the concentration of the two parameters (Electrical Conductivity and Total Dissolved Solid) and FEPA Permissible values.

Electrical conductivity gives an idea about the concentration of electrolytes in water and is a limiting factor. The high concentration of EC in this study is detrimental to crops production in the study area as well as human who eat such crops. Tanko (2002) asserted that the salinity of soil has influence on plant growth, crop yield and the quality of produce which is often determined by the salt concentration of irrigation water [5]. The optimum EC level for irrigation water is 2 millimho/cm, whilst if any value is above this level will reduce the water osmotic potential or the rate of water entry into the crops.

The pH which is the measurement of the acidity and alkalinity of water has a scale which ranges from 0-14. A pH of 7 means neutral and a pH less than 7 indicate acidity while the pH greater than 7 shows alkalinity. An irregular level of pH of water is rarely a problem. Therefore, the normal levels of a sample should be between 6.5 and 8 but values outside this range indicate that there are severe abnormalities in water quality. In this study the average pH value of the effluent samples is 7.0 (neutral) while the FEPA permissible limit is 6-9 (Table 1). This shows that the concentration of pH in the effluents is within the Permissible value set by FEPA. The high pH value in water can destroy bacterial and other microorganisms as well as inhibit self-purification of a stream.

Heavy Metals (HMs) concentrations in the industrial effluents

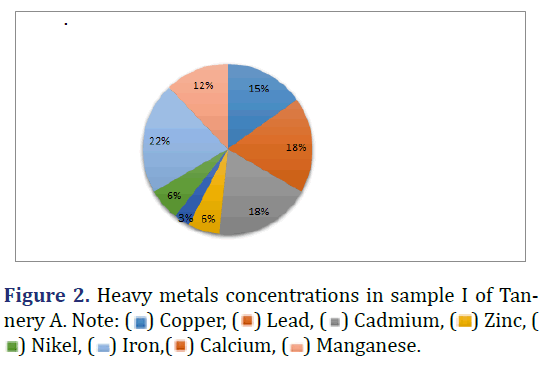

Figure 2, reveals the concentrations’ of the various heavy metals in the industrial effluents of sample I from tannery A and Calcium has the highest concentration of 22.00% followed by copper and cadmium with 18% respectively, and Lead with 15% while Nickel has the least concentration of 3% but all the heavy metals concentrations are still within the FEPA permissible limit. Study has proven that concentration of heavy metals in the environment occur due to continuous disposal of untreated industrial effluents generated during the operational phase of industries. Metals like hexavalent chromium, iron, manganese, copper, lead, cadmium and nickel etc. majorly produced by Textile and tannery [6].

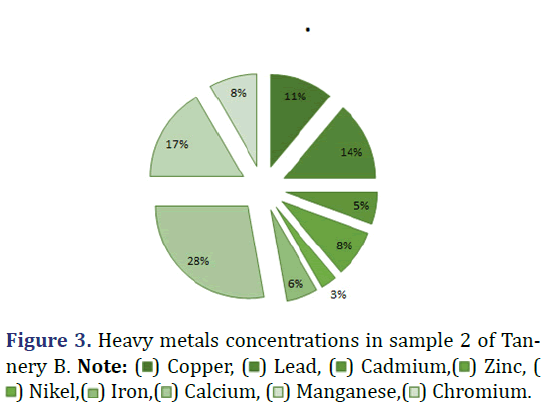

Figure 3, reveals the heavy metals concentrations in the industrial effluents of sample 2 from tannery B. The finding indicates that Calcium has the utmost concentration of 28% followed by manganese 17% and Lead 14% while the minimum concentration is Nickel 2.77%. The concentrations of all the heavy metals are within the FEPA permissible limit.

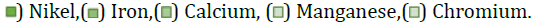

Figure 4 indicates that Calcium has the highest concentration of 63.07% in sample 3 of the industrial effluents from tannery A and B, of which Lead and Copper have 6.15% correspondingly while Nickel, Manganese and Chromium have 2.56% respectively being the least heavy metal present in the industrial effluents. However, the heavy metals concentrations are still within the FEPA permissible limit.

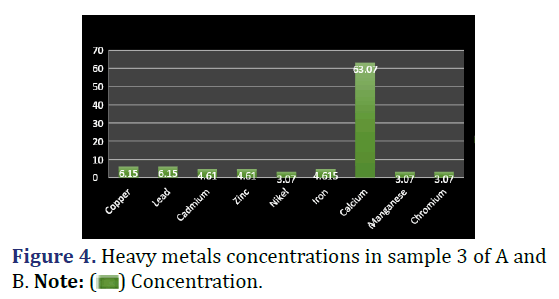

Figure 5 shows the various concentrations of heavy metals in the industrial effluents of sample 4 from tannery A and B. Calcium happens to be the maximum concentration of 35.29% followed by Cadmium 23.52%, then Copper and Lead with 11.76% respectively while the minimum concentration is 1.96%. Nevertheless, the heavy metals concentrations in the industrial effluents of sample 4 from the two tanneries fall within FEPA permissible limit.

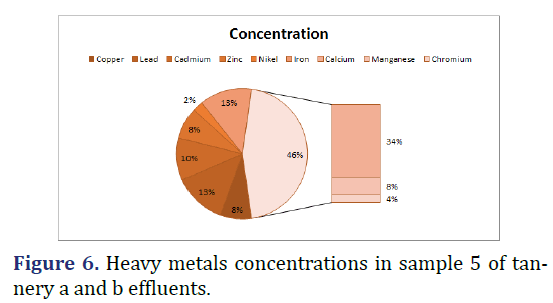

Figure 6 reveals the variation in the concentrations of heavy metals present in the industrial effluents’ sample 5 of the two tanneries. The result shows that Calcium emerges as the highest concentration with 33.33%, then Lead and Iron with 12.82% respectively, followed by Cadmium 10.25% while Nickel 2.56% happens to be the lowest concentration. However, all the heavy metals concentrations are within the FEPA permissible limit.

Heavy metals deficiency or excess could lead to a number of disorders but on the other hand they are significant for proper functioning of biological systems Ward (1995) [7]. Lead is found to be one of the most toxic heavy metal according to American Public Health Association (APHA).

Health and environmental impacts of the industrial effluents

It is factual that tannery and textile industries use the largest quantities of water and produce the highest amounts of wastewater that constitutes the main sources of pollution. The waste bi-products from tanneries often have high concentrations of heavy metals such as Chromium and Cadmium but in this study they were low. The field observation carried out and interview conducted for the residents of the study area revealed some impacts of industrial effluents on health and the environment which include air pollution. This problem has reached the extent that the people living in the environment and passerby find it hard to breathe in when the air is polluted by the effluents. Also, customers find it difficult to patronize the restaurant workers and other business people in the environment as a result of the smell from the effluents and the untidy environment caused by the industrial effluents.

Binns et al. (2003) asserted that industrial effluents do not only emits miasmal odours, but is an excellent breeding ground for disease vectors [8]. It was observed that there is severe harmful odour emanating from the discharged industrial effluents and these have serious effects on the people, and the occupational activities in the study area. Thus, the environment has become non conducive/ hygienic for people. Moreover, the people in the study area expressed their painful and uncomfortable feelings concerning the effluents but since the businesses are their means of livelihood they have to be in the excruciating condition in the environment so as to earn a living.

The major conspicuous and dangerous environmental challenges in the study area which the people are agonizing and lamenting for are odour and open drainages along the road which cause air pollution thereby making the environment untidy and unhealthy to the people in the area and the passerby. These cause sickness and low patronage to the businesswomen/men who sell food and goods in the study area, as the customers run away from them particularly as a result of the severe stinking odour from the industrial effluents. This odour is actually excruciating as it is very uncomfortable to stand in the environment most times when the effluent is stinking or humming after discharge. Different kinds of diseases have been attributed to the industrial effluent among which is malaria. The health hazards are associated with polluted peri-urban water sources. For transparency and evidence backing up this study, Figures 7-8 reveal some economic activities in the study area where the industrial effluents flow and emanate odour which negatively affects the workers and businessmen/women.

Environmental pollution is a colossal threat to human health, plants, soil and animals. Some of the business people who are respondents expressed their feelings on how they are uncomfortable with the odour from the effluents.

Indeed, this condition is worth agonising and lamenting over. The respondents stated that the residents of the study area have protested before now against the dangerous problem of effluents, yet this is ongoing till date. Also, they have complained to the industries and government but the problem has not been solved. The people revealed that they have not received any support or relief material from the industries and the government to tackle their challenges. The respondents are of the opinion that the government should tackle this problem which has become a serious threat to lives.

Means of discharging effluents from the industries

In the study area it was observed that the tannery B has underground pipe for effluents discharge but it is link to the road drainage after a little distance from the industry while the tannery A discharges effluents directory from the industry to the road drainage in the study area of which is not proper. The means in which the both industries release their effluents to the environment is inappropriate. Thus, there is need for the industries to develop better means of releasing the industrial effluents to the environment. This issue calls an urgent attention of the government to enforce the Federal Environmental Protection Agency (FEPA) laws on the industries for adequate solution to the environmental and people’s challenges in the study area.

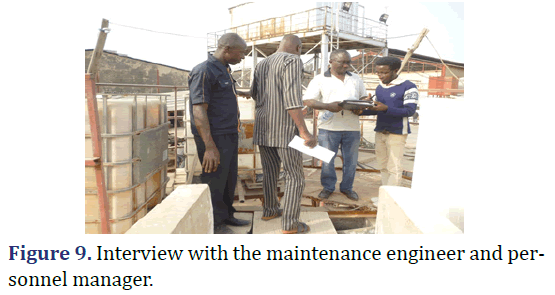

In the interview conducted for the industrial personnel of tannery B as shown in Figure 9, it was revealed by the maintenance engineer that the effluents are treated before discharge. The treatment plant and processes involve in treating the effluents were made known and explained lucidly. Despite this, the findings have apparently shown an indisputable proof of high air pollution and poor drainage of the environment. Moreover, the concentration of electrical conductivity and total dissolved solids appear to be the highest among all other parameters.

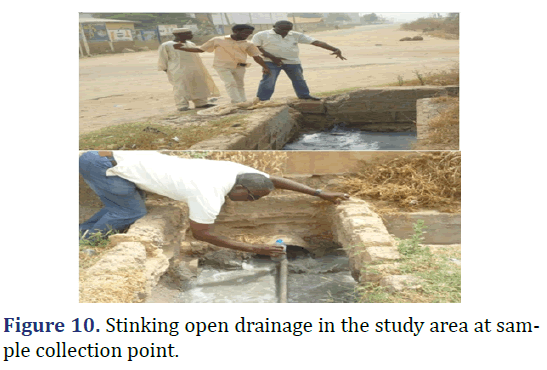

There is stagnant water in the environment because the tanneries industries discharge the effluent to environment since they have no reservoir which the effluents can be discharged into directly. This is responsible for diseases. Studies have shown that there has been a great deal of concern that stagnant water channels may increase the abundance of mosquito breeding sites and hence the risk of malaria and other vector-borne diseases [9,10,11]. Figure 10 shows an open local drainage where industrial effluents flow in the study area.

Open drainage is very detrimental to the environment and human health as different toxic chemicals and substances emanate from it. This can be prevented by adopting modern closed drainage system which helps in controlling air pollution.

Conclusion

Environmental pollution has become endemic in Sharada industrial area as due to stagnant water and the presence of heavy metals in the effluents that are regularly discharged into the environment. This menace has currently reached an alarming rate in the study areas the environmental pollution is very glaring and the inhabitants are not comfortable with the condition which is excruciating.

The protection of lives and sustainable hygienic environment are very significant. Thus, this study assessed the impact of environmental pollution on the residents of Sharada tanneries industrial area in Kano and has shown has shown that concentration of all the physicochemical parameters of the industrial effluents are within the acceptable limits except for the Electrical Conductivity and Total Dissolved Solid which have large disparity between the FEPA tolerant values. The industrial effluents are affecting lives, the environment and economic activities of the people in the study area. Thus, the government intervention for the control of this menace is needed and if nothing is done concerning this problem, in the nearest future, it will become more alarming and devastating to the environment and human’s health thereby resulting in loss of lives.

Authors Contributions

This study assessed the impact of environmental pollution and determined levels of heavy metals (HMs) in the effluents from tannery industries in Sharada phase I and II. The data used include laboratory test to determine heavy metals (Cd, Cr, Cu, Pb, Zn, Ni, Mn, Fe), Electrical Conductivity (EC) and Total Dissolved Solid (TDS) from industrial effluents.

Ethical Approval

Not Applicable

Consent to Participate

Not Applicable

Consent to Publish

Dave E. Ekpa, the author of this article wants it to be published.

Funding

Not Applicable

Competing Interests

Not Applicable

Availability of Data and Materials

Primary and secondary data were sourced by the author through field survey, interview, physical observation and previous works on the subject matter.

References

- Fereidoun H, Nourddin MS, Rreza NA, Mohsen A, Ahmad R, Pouria H. The Effect of Long-Term Exposure to Particulate Pollution on the Lung Function of Teheranian and Zanjanian Students. Pak J Physiol 2007; 3:1-5.

- Gana AJ, Toba AP. Environmental Pollution and Sustainability. Journal of Research in Environmental Science and Toxicology 2015; 4:1-9.

- Bello OS, Inyinbor AA, Dada AO, Oluyori AP. Impact of Nigerian Textile Industry onEconomy and Environment: a Review. Inter J of Basic & Applied Sci 2013; 13.

- Falola JA, Kano S, Okafor E, Osaghae C, Ikporukpo S, Abumere. Africa Atlases: Atlas of Nigeria. 2002.

- Tanko AI. Spatio-temporal patterns of environmental pollution. University of Ilorin 2002.

- Deepali, Gangawar kk. Metals Concentration in Textile and Tannery Effluents, Associated Soils and Ground Water. New York Science Journal 2010; 3:1-8.

- Militan AB, Alajtal AI, Alsadawy AM. Toxicity of Heavy Metals and Microbial Analysis of Soil Samples Collected from the Area around Zliten Cement Factory. Open Journal of Air Pollution. 2013

- Binns JA, Maconachie RA, Tanko AI. Water, land and health in urban and peri-urban food production: The case of Kano, Nigeria. Land Degradation & Development 2003; 14: 431–444.

- Lindsay SW, Campbell H, Adiamah JH, Greenwood AM, Bangali JE, Greenwood BM. Malaria in a peri-urban area of The Gambia. Ann Trop Med Parasitol 1990; 84: 553–562.

[crossref] [Google scholar] [Pubmed]

- Trape JF, Lefebvre-Zante E, Legros F, Ndiaye G, Bouganali H, Druilhe P, et al. Vector density gradients and the epidemiology of urban malaria in Dakar, Senegal Am J Trop Med Hyg 1992; 47: 181–189.

[crossref] [Google scholar] [Pubmed]

- Trape J-F, Zoulani A. Malaria and urbanization in central Africa: the example of Brazzaville. Part III: Relationships between urbanization and the intensity of malaria transmission. Trans R Soc of Trop Med Hyg 1987; 81: 19–25.

[crossref] [Google scholar] [Pubmed]

Copyright: © 2022 The Authors. This is an open access article under the terms of the Creative Commons Attribution NonCommercial ShareAlike 4.0 (https://creativecommons.org/licenses/by-nc-sa/4.0/). This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

) Railroad, (

) Railroad, ( ) Minor Road, (

) Minor Road, (  ) Major

Road, (

) Major

Road, ( ) Sharada, (

) Sharada, ( ) Other Areas.

) Other Areas.

) Copper, (

) Copper, ( ) Lead, (

) Lead, (  ) Cadmium, (

) Cadmium, ( ) Zinc, (

) Zinc, ( ) Nikel, (

) Nikel, ( ) Iron,(

) Iron,( ) Calcium, (

) Calcium, ( ) Manganese.

) Manganese.

) Concentration.

) Concentration.

) Concentration.

) Concentration.